Honed tube for hydraulic cylinder usually is known as hydraulic cylinder tube or cylinder tubing also. It is mostly produced with cold drawn seamless tube (CDS tube) or DOM tube by honing or skiving & roller burnishing on the inner diameter of the steel tube.

Our factory is a high quality honed tube manufacturer and supplier in China. We produce and supply a wide range of honed tubes for hydraulic cylinders, with many different materials.

Product Description

Seamless steel honed tube for hydraulic cylinder have the precise tolerance.

Product Name: Honed tube for hydraulic cylinder

Also known as cylinder tube, hydraulic cylinder tubing, honed ID tubing, honed cylinder tube, and more.

Our Honed tube for hydraulic cylinder is a crucial component in various industries. Made from our factory’s own cold drawn seamless tube (CDS tube), the honed tube undergoes honing or skiving and roller burnishing processes.

Quality Standards:

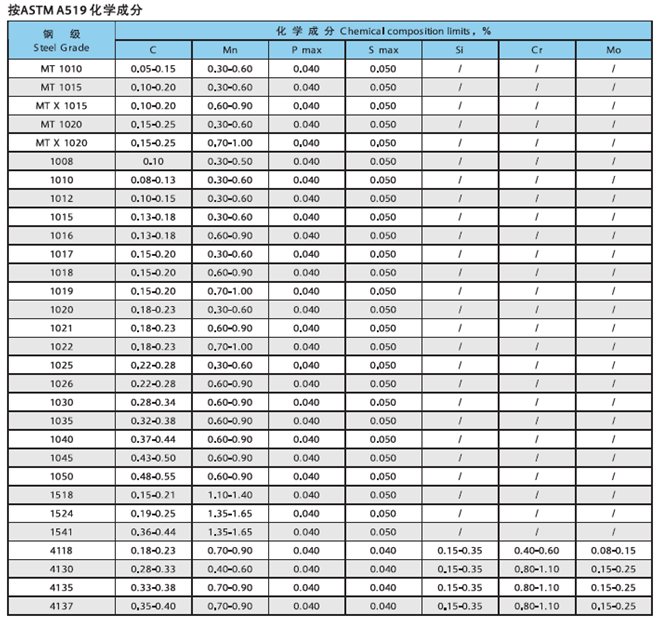

Our honed hydraulic cylinder tube is manufactured in accordance with industry standards such as:

- DIN 2391, EN10305-1, ASTM A519 /A519M, ASTM A513 /A513M, JIS G344,

- and so on.

Size Availability:

We supply honed tubes in both metric and imperial dimensions, with sizes ranging from I.D 30 mm to I.D 500 mm (1.5″ – 20″), Wall thickness 3 – 50 mm (1/8″ – 2″)

Steel Grades:

We manufacture honed tubes in a wide range of carbon and stainless steel grades, including:

Carbon steel Hydraulic Cylinder Tube is available with grades as below:

- E355, S355

- ST 52, ST52.3, ST 52.4,

- SAE 1020

- SAE 1026

- SAE1030/1035

- St35, St 37.4

- E255, E215, E235

Stainless steel Honed tube can be supplied in grades as below:

- TP 304 / 304L

- TP316 / 316L

- TP 316Ti

Other steel grades of hone tube /honed pipe is available on customer’s request.

Specifications Comparison table

| Items | China | Steel Grade | European Uion | Steel Grade | American | Steel Grade | Germany | Steel Grade |

| Precision Seamless Tube | GB3639 | 10,20,Q345,42CrMo | EN 10305-1 | E215,E235,E355,42CrMo4 | AST MA519 | 1010,1020,1026,104541304140 | DIN2391,BK,BKS | ST35,ST37,ST 52 |

Chemical&mechanical properties

| EN 10305/EN 10305-4 | DIN2391 | ||||||||||||

| Chemical composition%(max) | Steel Gr, | C | Si | Mn | P | S | Chemical composition%(max) | Steel Gr. | C | Si | Mn | P | S |

| E215 | 0.10 | 0.35 | 0.70 | 0.025 | 0.025 | ST 35 | 0.10 | 0.35 | 0.40 | 0.025 | 0.025 | ||

| E235 | 0.17 | 0.35 | 1.20 | 0.025 | 0.025 | ST 37 | 0.17 | 0.35 | 1.20 | 0.025 | 0.025 | ||

| E355 | 0.22 | 0.55 | 1.60 | 0.025 | 0.025 | ST 52 | 0.22 | 0.55 | 1.60 | 0.025 | 0.025 | ||

| Delivery Condition | Delivery Condition | ||||||||||||

| +C | No heat treatment afterthe final cold drawing process | BK | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation | ||||||||||

| +LC | After the final heat treatment there’s a suitable drawing pass | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming(e.g. Bending, expanding) | ||||||||||

| +SR | After the final cold drawing process there’s a stress relief heat treatment in controlled atmosphere | BKS | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree | ||||||||||

| +A | After the cold drawing process the tubes are annealed in a controlled atmosphere | GBK | The last cold forming process is followed by a nnealing in a controlled atmosphere | ||||||||||

| +N | After the final cold drawing operation the tubes are normalized in a controlled atmosphere | NBK | The last cold forming process is followed by annealing above theupper transformation point in a controlled atmosphere | ||||||||||

| Mechanical Properties | Mechanical Properties | ||||||||||||

| Steel Gr. | +C | +LC | +SR | +A | +N | Steel Gr. | BK | BKW | BKS | GBK | NBK | ||

| Tensile Strength (Rm)(MPa)Min | E215 | 430 | 380 | 380 | 280 | 290-430 | Tensile Strength (Rm)(MPa)Min | ST 30AL | 430 | 380 | 380 | 280 | 290-430 |

| E235 | 480 | 420 | 420 | 315 | 340-480 | ST 37 | 440 | 370 | 380 | 315 | 340-470 | ||

| E355 | 640 | 580 | 580 | 450 | 490-630 | ST 52 | 640 | 580 | 580 | 450 | 490-630 | ||

| Yield Strength (ReH)(MPa)Min | E215 | ≥0.8Rm | ≥0.7Rm | 280 | ≥0.5Rm | 215 | Yield Strength (ReH)(MPa)Min | ST 30AL | ≥0.8Rm | ≥0.7Rm | 280 | ≥0.5Rm | 215 |

| E235 | ≥0.8Rm | ≥0.7Rm | 280 | ≥0.5Rm | 235 | ST 37 | ≥0.8Rm | ≥0.7Rm | 280 | ≥0.5Rm | 235 | ||

| E355 | ≥0.8Rm | ≥0.7Rm | 450 | ≥0.5Rm | 355 | ST 52 | ≥0.8Rm | ≥0.7Rm | 420 | ≥0.5Rm | 355 | ||

| Elongation % | E215 | 8 | 12 | 16 | 30 | 30 | Elongation % | ST 30AL | 6 | 10 | 16 | 25 | 25 |

| E235 | 6 | 10 | 16 | 25 | 25 | ST 37 | 6 | 10 | 16 | 25 | 25 | ||

| E355 | 4 | 7 | 10 | 22 | 22 | ST 52 | 4 | 7 | 10 | 22 | 22 | ||

| a. ST 30Al with Aluminium composition min 0.025% | |||||||||||||

| OD TOLERANCE | |||||||||||||

| OVER | UP TO AND INCLUDING | TOLERANCE | |||||||||||

| MM | MM | MM+/- | |||||||||||

| 30 | 0.10 | ||||||||||||

| 50 | 70 | 0.15 | |||||||||||

| WALL TOLERANCE | |||||||||||||

| The tolerance including ecentricity, shall be +/- 10% with a minimum of +/- 0.10mm | |||||||||||||

| STRAIGHTNESS | |||||||||||||

| Tubes shall not depart from straightness by more than 1.5 mm/m |

Honed Tube Sizes

Our factory produces honed tubes with size from ID 30mm to ID 500 mm, and with tolerance H7, H8, H9, H10 upon customers’ request. The length of our cylinder honed tube can be max 15 meters. We supply honed tubes with fixed length and random length according to customers’ requirements.

For more cylinder tube size information, Please refer to our standard honed tube sizes.

Contact Us

Want more information or want a price offer? Please contact us as below.

Contact Person: Long

E-MAIL: [email protected]

Phone: +86-177-75807583