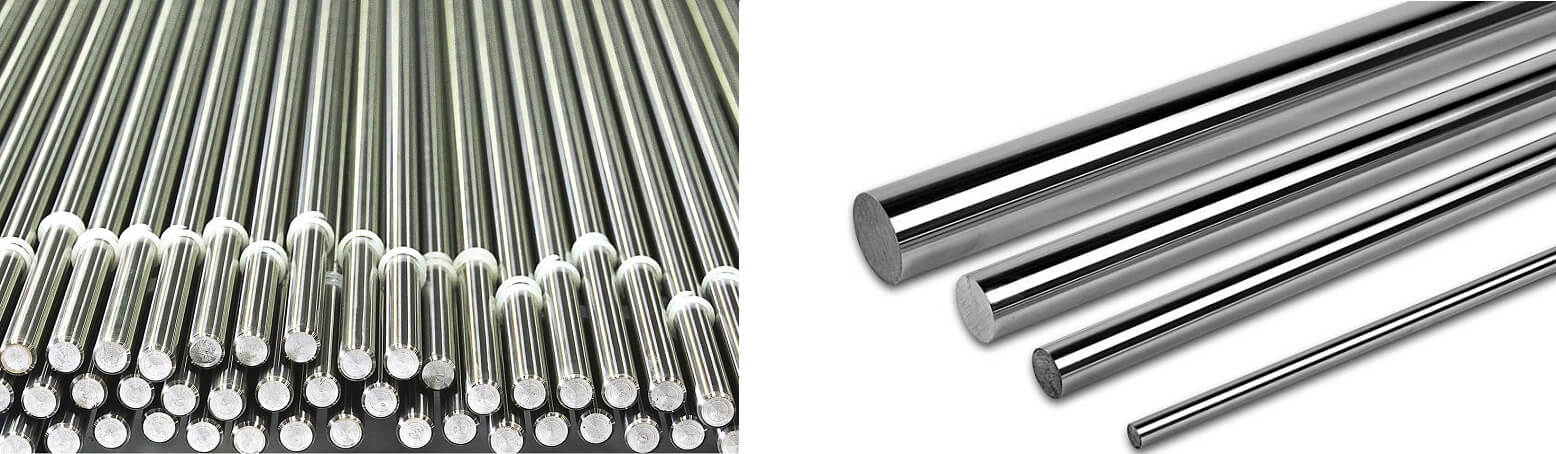

Hard chrome plated rod, also is well-known as hard chrome plated bar, hard chrome plated shafting, hard chrome plated shaft, and chrome rods for hydraulic cylinders, are manufactured from cold rolled or hot rolled carbon steel round bars. These bars undergo a meticulous process of centerless grinding and polishing before being plated with chrome to a thickness of at least 20 microns (0.0008 inches). The chrome plating provides exceptional corrosion resistance and a shiny finish, making them perfect for use in hydraulic cylinders.

Chrome plated bar: Product Introduction

Chrome Plated Bar: Product Description

Product Brand

Yiwu is our brand name.Product Standards

Our chrome plated bar is made to meet customers’ specifications, and conforms to the following standards.

- ASTM A311,

- ASTM A108

- other popular standards.

Available Steel grades for chrome bar:

Our hard chrome plated shafts are available with steel grade of SAE 1045, CK 45, C45; and stainless steel available on request.

Chrome rod Dimension range(outer diameter):

Metric size: External diameter 6 mm to 900 mm;

Imperial size chrome bar available from 1/4″ to 32″

Length of chrome plated bar:

Our factory is capable of providing chrome rods for hydraulic cylinders with a length that can range from random to a specific, fixed length as per the customer’s request. The maximum length available for our chrome rods is 12 meters.

Diameter Tolerance of chrome plated bars:

ISO f7, f8, g6 or on customers’ request.

Surface roughness

The surface roughness of our factory’s hard chrome plated shafts is around Ra0.2μm(8 Ra), max. Ra0.4μm (16 Ra).

Hard Chrome Plated Thickness:

The chrome plating on our cylinder rod typically has a minimum thickness of 20 microns (0.0008 inches). Other plating thicknesses are available upon request, with a maximum thickness of 100 microns. Our chrome steel bars have been tested to withstand a salt spray test for at least 72 hours (10 microns thickness), in accordance with ASTM B-117 standards.

Packing of chrome plated shafts

Our chrome plated rods are packaged in cardboard tubes to ensure protection of the outer diameter during moving, loading, transportation, shipping and unloading.

Custom made diameters and chrome thickness of the chrome steel bar is available upon request.

Our factory’s chrome rod for hydraulic cylinders is available with or without Hardened Induction heat treatment.

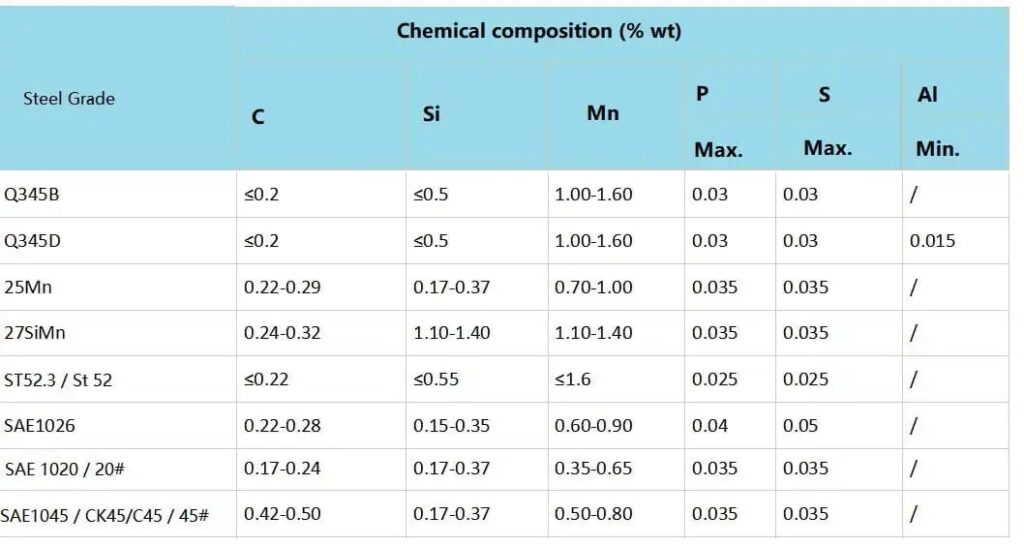

Hard chrome plated shafts: Material Chemical composition

As a prominent China chrome plated bar manufacturer and supplier, we satisfy customers’ demands by offering chrome plated rods in medium carbon steel grades. The most commonly used steel grades include AISI 1045, JIS S45C, SAE1045, DIN CK45, SAE 4140, and 42CrMo. Omong these, SAE 1045, CK45 are the most popular steel grades of the chrome bars.

Here below is the chemical composition of steel grade SAE 1045 / CK45:

| Steel Grade | Chemical Composition % | ||||

| Carbon | Mn | Si | P | S | |

| SAE 1045 | 0.43-0.50 | 0.60-0.90 | – | 0.040 Max | 0.050 Max |

| CK 45 | 0.42-0.50 | 0.50-0.80 | 0.40 Max | 0.035 Max | 0.035 Max |

Here’s the chemical composition of 4140 chrome plated bar for shafts.

| SAE 4140 | C% | Si% | Mn% | P% | S% | Cr% | Mo% |

| Min | 0.36 | 0.1 | 0.65 | 0.75 | 0.15 | ||

| Max | 0.44 | 0.4 | 1.1 | 0.04 | 0.04 | 1.2 | 0.35 |

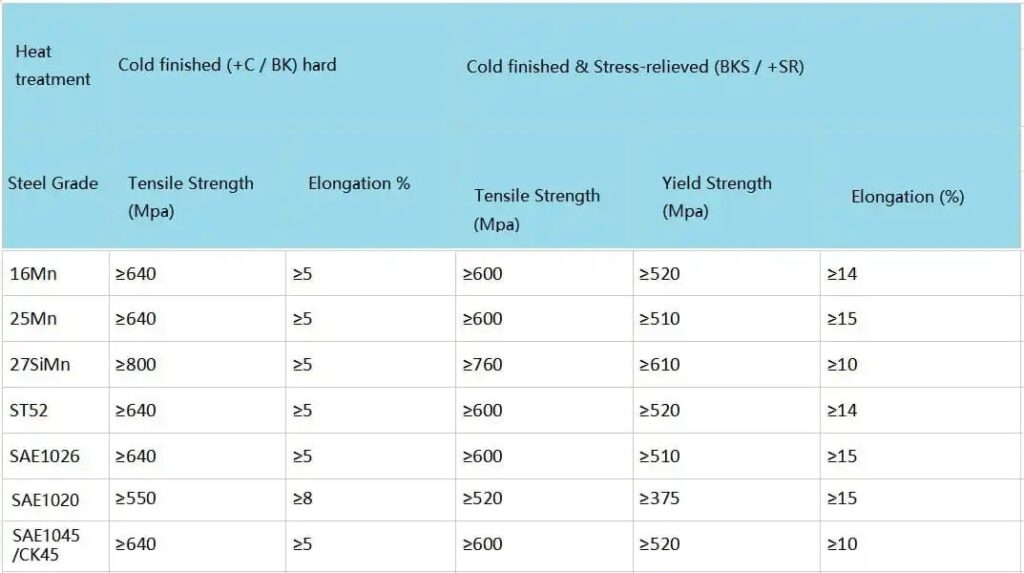

Chrome plated shafting: Mechanical Properties

| Steel Grade | Mechanical Properties | |||

| Yield Strength | Tensile Strength | Elongation | Hardness | |

| SAE 1045 | 75000 psi / 517 Mpa | 85000 psi / 585Mpa | 10% | Rc 60-72 |

| CK 45 | 75000 psi / 517 Mpa | 85000 psi / 585Mpa | 10% | Rc 60-72 |

Our chrome plated rod can achieve a minimum yield strength of 100K psi (690 Mpa) through specialized heat treatment.

For applications that demand high strength, we offer SAE 4140 hard chrome plated bar. The following are the mechanical properties of SAE 4140:

| 4140 | Yield strength | Tensile Strength | Elongation | Hardness HB |

| Min | 800 Mpa /115K psi | 900 Mpa /130K psi | 20% | 270 HB |

In addition, our chrome plated bar can be supplied with other types of materials, here below is a list of the materials.

Chrome plated piston rod Dimensions

As a top-notch China hard chrome plated rod manufacturer and chrome rod supplier, we produce chrome plated rods with an outer diameter of up to 900 mm. The following are some of the common sizes:

| Diameter(imperial size) | Weight per Foot | Diameter(metric size) | Weight per Meter | ||||||||

| (Inches) | (Lbs.) | mm | (KG.) | ||||||||

| 0.375 | 0.375 | 10 | 0.62 | ||||||||

| 0.438 | 0.512 | 12 | 0.89 | ||||||||

| 0.5 | 0.668 | 14 | 1.21 | ||||||||

| 0.625 | 1.043 | 15 | 1.39 | ||||||||

| 0.688 | 1.264 | 16 | 1.58 | ||||||||

| 0.75 | 1.502 | 17 | 1.78 | ||||||||

| 0.875 | 2.044 | 18 | 2 | ||||||||

| 0.938 | 2.349 | 20 | 2.47 | ||||||||

| 1 | 2.67 | 22 | 2.98 | ||||||||

| 1.063 | 3.017 | 25 | 3.85 | ||||||||

| 1.125 | 3.379 | 28 | 4.83 | ||||||||

| 1.188 | 3.768 | 30 | 5.55 | ||||||||

| 1.25 | 4.172 | 32 | 6.31 | ||||||||

| 1.313 | 4.603 | 35 | 7.55 | ||||||||

| 1.375 | 5.048 | 36 | 7.99 | ||||||||

| 1.5 | 6.008 | 40 | 9.86 | ||||||||

| 1.563 | 6.523 | 45 | 12.48 | ||||||||

| 1.625 | 7.05 | 50 | 15.41 | ||||||||

| 1.688 | 7.608 | 55 | 18.65 | ||||||||

| 1.75 | 8.177 | 56 | 19.33 | ||||||||

| 1.875 | 9.387 | 60 | 22.19 | ||||||||

| 1.938 | 10.028 | 63 | 24.47 | ||||||||

| 2 | 10.68 | 65 | 26.05 | ||||||||

| 2.125 | 12.057 | 70 | 30.21 | ||||||||

| 2.25 | 13.517 | 75 | 34.68 | ||||||||

| 2.375 | 15.06 | 80 | 39.46 | ||||||||

| 2.5 | 16.688 | 85 | 44.54 | ||||||||

| 2.625 | 18.398 | 90 | 49.94 | ||||||||

| 2.75 | 20.192 | 95 | 55.64 | ||||||||

| 2.875 | 22.069 | 100 | 61.65 | ||||||||

| 3 | 24.03 | 105 | 67.97 | ||||||||

| 3.25 | 28.202 | 110 | 74.6 | ||||||||

| 3.375 | 30.413 | 115 | 81.53 | ||||||||

| 3.5 | 32.708 | 120 | 88.78 | ||||||||

| 3.625 | 35.085 | 125 | 96.33 | ||||||||

| 3.75 | 37.547 | 130 | 104.19 | ||||||||

| 4 | 42.72 | 140 | 120.83 | ||||||||

| 4.25 | 48.227 | 150 | 138.71 | ||||||||

| 4.5 | 54.068 | 160 | 157.82 | ||||||||

| 4.75 | 60.242 | 170 | 178.17 | ||||||||

| 5 | 66.75 | 180 | 199.75 | ||||||||

| 5.25 | 73.592 | 200 | 246.6 | ||||||||

| 5.5 | 80.768 | 250 | 385.31 | ||||||||

| 6 | 96.12 | ||||||||||

| 6.5 | 112.808 | ||||||||||

| 7 | 130.83 | ||||||||||

| 7.5 | 150.188 | ||||||||||

| 8 | 170.88 | ||||||||||

| 8.5 | 192.908 | ||||||||||

| 9 | 216.27 | ||||||||||

| 10 | 267 | ||||||||||

| 11 | 323.07 | ||||||||||

| 12 | 384.48 | ||||||||||

| Note: Other sizes are available on customer’s request, Our Chrome rod max size is diameter 900 mm. | |||||||||||

Chrome steel bar: Dimension tolerance

Our chrome rods can be supplied with tolerance of g6, f7, f8 and f9 on customers’ request. Here below is the tolerance chart.

| Tolerances for Chrome Shafts (ISO 286-2) | |||||||||||

| over | up to | Upper and Lower limits in micrometer (0.001 mm) | |||||||||

| d9 | e8 | f7 | g6 | h5 | h6 | h7 | h8 | h9 | h11 | ||

| – | 3 | -20 | -14 | -6 | -2 | 0 | 0 | 0 | 0 | 0 | 0 |

| -45 | -28 | -16 | -8 | -4 | -6 | -10 | -14 | -25 | -60 | ||

| 3 | 6 | -30 | -20 | -10 | -4 | 0 | 0 | 0 | 0 | 0 | 0 |

| -60 | -38 | -22 | -12 | -5 | -8 | -12 | -18 | -30 | -75 | ||

| 6 | 10 | -40 | -25 | -13 | -5 | 0 | 0 | 0 | 0 | 0 | 0 |

| -76 | -47 | -28 | -14 | -6 | -9 | -15 | -22 | -36 | -90 | ||

| 10 | 18 | -50 | -32 | -16 | -6 | 0 | 0 | 0 | 0 | 0 | 0 |

| -93 | -59 | -34 | -17 | -8 | -11 | -18 | -27 | -43 | -110 | ||

| 18 | 30 | -65 | -40 | -20 | -7 | 0 | 0 | 0 | 0 | 0 | 0 |

| -117 | -73 | -41 | -20 | -9 | -13 | -21 | -33 | -52 | -130 | ||

| 30 | 50 | -80 | -50 | -25 | -9 | 0 | 0 | 0 | 0 | 0 | 0 |

| -142 | -89 | -50 | -25 | -11 | -16 | -25 | -39 | -62 | -160 | ||

| 50 | 65 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

| -174 | -106 | -60 | -29 | -13 | -19 | -30 | -46 | -74 | -190 | ||

| 65 | 80 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

| -174 | -106 | -60 | -29 | -13 | -19 | -30 | -46 | -74 | -190 | ||

| 80 | 100 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

| -207 | -126 | -71 | -34 | -15 | -22 | -35 | -54 | -87 | -220 | ||

| 100 | 120 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

| -207 | -126 | -71 | -34 | -15 | -22 | -35 | -54 | -87 | -220 | ||

| 120 | 140 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 140 | 160 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 160 | 180 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 180 | 200 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 200 | 225 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 225 | 250 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 250 | 280 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

| -320 | -191 | -108 | -49 | -23 | -32 | -52 | -81 | -130 | -320 | ||

| 280 | 315 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

| -320 | -191 | -108 | -49 | -23 | -32 | -52 | -81 | -130 | -320 | ||

| 315 | 355 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

| -350 | -214 | -119 | -54 | -25 | -36 | -57 | -89 | -140 | -360 | ||

| 355 | 400 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

| -350 | -214 | -119 | -54 | -25 | -36 | -57 | -89 | -140 | -360 | ||

What are the advantages of our chrome plated bar?

Customers have a preference for our factory’s chrome rod for hydraulic cylinders due to its several advantageous features, including:

a. Precise tolerances, that guarantee a perfect fit when used to make hydraulic piston rods.

b. The use of top-quality carbon steel that provides a balance of strength, hardness, and wear resistance while maintaining formability, weldability, and durability.

c. Chrome plating that offers corrosion resistance and a highly reflective appearance (Extremely reflective look);

d. High Strength: The yield strength of chrome plated bars can be 75000 psi up to 100000 psi, depends on the material and heat treatment method.

e. Excellent hardness: with a minimum surface hardness of HV850 and above, which not only enhances wear resistance but also increases the lifespan of the chrome plated rods, resulting in cost savings for the customer.

Applications of Chromed Bar

As a commonly used component in hydraulic and pneumatic systems, chrome plated bar is widely referred to as body material of hydraulic cylinder rod. Its primary purpose is for use in the production and repair of hydraulic and pneumatic piston rods.

In addition to its use in hydraulic and pneumatic piston rods, chrome plated bar can also be utilized in applications that demand a high-quality surface finish and precise dimensional tolerance.

Chrome plated bars are widely used in various industries due to their unique properties, including:

- Hydraulics and Pneumatics: Chrome plated bars are used as shafts and pistons in hydraulic and pneumatic systems due to their high strength and resistance to corrosion and wear.

- Material Handling: Chrome plated bars are used in conveyor systems, cranes, and hoists as they offer high load-bearing capacity and low friction.

- Robotics: Chrome plated bars are used in robotic systems due to their durability and precision.

- Machinery: Chrome plated bars are used in various types of machinery, including presses, punches, and die-casting machines, due to their high strength and resistance to wear and tear.

- Automotive: Chrome plated bars are used in the production of automotive components, such as suspension systems, due to their high strength and durability.

- Industrial Equipment: Chrome plated bars are used in the production of industrial equipment, such as pumps and compressors, due to their high strength and resistance to corrosion.

These are just some of the common applications of chrome plated bars. The exact application will depend on the specific requirements of the user, such as size, strength, and corrosion resistance.

Chrome plated bar: Product Packing

Packing is the last and important step to ensure the quality of the chrome plated bar. Good packing can protect the chrome plated rods surface from damaging during moving, loading, transportation, unloading.

The packing method of chrome plated bars is similar to the packing method of hydraulic cylinder tubes, as both require protection from impact and abrasion during transportation and storage. However, the packing method of chrome plated bar is stricter and more important than that of the hydraulic cylinder tubes. Because even the slightest damage to the outer surface cannot be accepted.

The following are our standard packing methods for chrome plated bars:

- Every chrome bar will be oiled slightly to prevent from rusty;

- Each chrome bar need to be put into a separated cardboard tube, to protect the outer surface of the chrome steel bar;

- Then the chrome bar packed in cardboard tube will be put into wooden boxes or wrap with ropes.

Chrome Plated Bar Packing Photos

Questions & Answers about Chrome Plated Bar

Question 1: What is the lead time of Chrome plated rods?

Answer: As one of the leading China chrome plated bar suppliers, we stock a lot of different sizes and materials of mother steel rods, so normally our delivery time is 10 – 20 days depends on the quantity and size.

Question 2: How can you ensure the quality of the hard chrome plated rods?

Answer: Yes, we execute Total Quality Management System in our chrome plated bar factory. We only use raw materials (round steel bar) made in China top quality steel maker such as TPCO, Sha-Steel, Huaigang Special Steel and so on. And we will inspect every chrome plated bar before packing, the hard chrome plated rod will be supplied with mill test certificate according to EN 10204 /3.1.

Question 3: Is your company chrome plated bar manufacturer or supplier trading company?

Answer: We are true chrome plated bar factory company located in Wuxi, Jiangsu, we are one of the professional chrome plated bar and hydraulic cylinder tube manufacturers in China, we welcome customers to come to visit our factory. Then you can see the details.

Question 4: How can you protect the outer surface of the chromed steel bars from damage during transportation?

Answer: To protect the outer surface of the hard chrome plated bar, we will put each chromed rod into a paper tube (cardboard sleeve). And then we will pack the chromed bar into wooden cases.

Question 5: Did you export your chrome plated shafts to oversea countries? And what is your main oversea market?

Answer: Yes, as the one of the largest chrome plated shaft suppliers in China, we exported our chrome plated shaft to many customers in oversea countries, our main market including USA, Vietnam, Australia, Russia, UAE, Canada, South Africa, Thailand, Brazil, etc.

Question 6: Will chrome plated steel bar rust?

Answer: No, Steel rod with Chrome plating will not rust, however when the chrome plating is damaged – it can appear dull. The steel core can rust if plating is lost through accidental damage or with natural wear over time.

Besides chrome plated rods, we also produce and supply induction hardened chrome plated cylinder rods.

Mob: +8617775807583

Why Choose us?

Listed below are the key benefits of our products and services.

- With nearly three decades of experience in chrome plated bar production, our factory possesses a wealth of knowledge in meeting customer requirements and delivering top-notch products.

- Our cutting-edge manufacturing equipment, including cold drawing machines, straightening machines, and heat treatment furnaces, enables us to create chrome plated rods with exceptional precision and consistency.

- We utilize high-quality raw materials from reputable steel manufacturers in China to ensure the superior quality of our honed tubes. Our chrome plated bars are manufactured with tight tolerances and high precision, making them ideal for hydraulic cylinder applications.

- To safeguard the longevity of our chrome plated shafts, they are coated with rust-preventing oil prior to shipment and protected during transit with cardboard tubes.

- Our rigorous quality control processes, including various tests and inspections, guarantee that only top-notch products leave our facility. With a mature quality management system in place, we ensure that every aspect of our business related to product quality is closely monitored and controlled.

- Our chrome plated rods have gained recognition worldwide and are trusted by customers in various industries across the globe.