Honed Hydraulic Cylinder Tube Brief Introduction

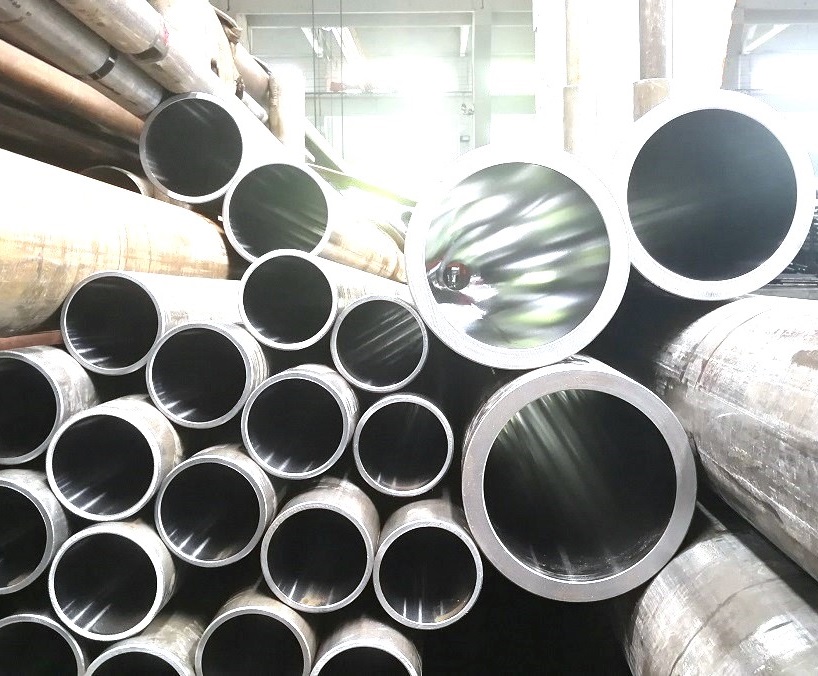

Honed tube, also referred to as Honed cylinder Tube, is a popular choice for hydraulic cylinder applications due to its ready-to-use nature without the need for further ID processing. These tubes, whether skived or roller burnished, play a vital role in the manufacturing of hydraulic cylinders. Yiwu Hydraulics, a reputable supplier and manufacturer of honed tubes, offers top-quality steel honed tubes and skived roller burnished tubes for pneumatic and hydraulic cylinders at competitive prices.

With nearly 30 years of experience in the industry, Yiwu Hydraulics is a trusted provider of honed tubes for hydraulic cylinder applications. We provide both metric and imperial sizes of honed tubing to cater to the diverse needs of our clients. Check out the details of our honed tube products below.

Honed tube: Product Description

Product Name: Honed tube

Commonly referred to as hydraulic cylinder tube, cylinder tubing, ID honed tubing, and honed cylinder tube, our Honed tube plays a vital role in a wide range of industries.

Crafted from cold drawn seamless tube (CDS tube) produced in our own factory, the honed tube is meticulously honed or skived and roller burnished to ensure top-quality performance.

Quality Standards:

Our honed tube for hydraulic cylinder is manufactured in accordance with the most popular industrial standards including:

- EN10305-1: Steel tubes for precision applications –Technical delivery conditions Part 1: Seamless cold drawn tubes

- DIN 2391 part 1: Seamless precision steel tubes – Dimensions

- DIN 2391 part 2: Seamless precision steel tubes – Technical delivery conditions

- ASTM A519 /A519M: Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

- ASTM A513 /A513M: Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

- JIS G3445: Carbon Steel Tubes for Machine Structural Purposes

- and more, or as per customer requirements.

Size Availability:

Steel Grades:

We manufacture honed cylinder tubes in a wide range of carbon steel and stainless steel grades, including:

Carbon steel Hydraulic Cylinder Tube is available with grades as below:

- E355, S355

- ST 52, ST52.3, ST 52.4,

- St35, St 37.4

- E255, E215, E235

- SAE 1020

- SAE 1026

- SAE1030/1035

Stainless steel Honed tube can be supplied in grades as below:

- TP 304 / 304L / 1.4301 /1.4307

- TP316 / 316L / 1.4401 /1.4404

- TP 316Ti /1.4571

Other steel grades of hone tube /honed pipe is available on customer’s request.

Specifications of main materials of hydraulic cylinder tube

- The inner diameter surface roughness of honed cylinder tube : Ra 0.2μm(RA8)-0.4 μm (RA16)

- The chemical composition & mechanical properties of the main steel grades for hydraulic cylinder honed tube is listed as below.

| Grade | Chemistry | % | Yield | Tensile | Elongation | Typical Hardness |

|---|---|---|---|---|---|---|

| PSI | PSI | % in 2″ section | Min | |||

| 1020 | Carbon | 0.150 – 0.200 | 60,000 | 70,000 | 10 | B-75 |

| Mn | 0.300 – 0.600 | |||||

| P | 0.035 Max | |||||

| S | 0.035 Max | |||||

| ST52.3 / E355 | Carbon | 0.140 – 0.180 | 75,000 (518Mpa) | 85,000 (587Mpa) | 15 | B-80 |

| Si | 0.150 – 0.300 | |||||

| Mn | 1.200 – 1.400 | |||||

| P | 0.020 max | |||||

| S | 0.010 max |

Main Applications of Honed tubing

Honed tubing and skived and roller burnished tubes are frequently used as cylinder tubes, such as hydraulic cylinder tubes and pneumatic cylinder tubing, for manufacturing and repairing hydraulic and pneumatic cylinders. The precise dimension tolerance and polished surface of honed tubes make them perfect for applications that demand accuracy and high surface quality. In addition to cylinder tubes, honed tubes are also suitable for a variety of other uses, including Precision Mechanical Tubes, Hydraulic Cylinders, Multi-Joint Tubes in construction, Steel Axis Pipes, Injection Machines, Robotic Arms, and more.

Our factory manufactures a broad range dimensions of cylinder tubes to meet both metric and imperial dimensions.

- Metric dimension honed tubes:

Available in I.D sizes from 30 mm to 800 mm and wall thicknesses from 3 mm to 50 mm. - Imperial dimension (inch size) honed tubes:

Available in sizes ranging from 1.5″ to 30.0″ I.D and wall thicknesses from 1/8″ to 2″. - Length:

We provide the option of either random or fixed lengths up to 14 meters for both metric and imperial dimensional honed cylinder tubes.

For reference, a chart of standard metric and imperial sizes of honed tube is available as below.

Chart 1. honed cylinder tube Metric sizes

Inside diameter | Outside Diameter | Wall thickness | Length |

mm | mm | mm | m |

| 32 | 40 | 4 | 6 |

| 35 | 45 | 5 | 6 |

| 40 | 50 | 5 | 6 |

| 50 | 60 | 5 | 6 |

| 55 | 65 | 5 | 6 |

| 60 | 70 | 5 | 6 |

| 60 | 75 | 7.5 | 6 |

| 60 | 80 | 10 | 6 |

| 63 | 75 | 6 | 6 |

| 63 | 78 | 7.5 | 6 |

| 65 | 75 | 5 | 6 |

| 65 | 80 | 7.5 | 6 |

| 70 | 80 | 5 | 6 |

| 70 | 85 | 7.5 | 6 |

| 70 | 90 | 10 | 6 |

| 75 | 90 | 7.5 | 6 |

| 75 | 95 | 10 | 6 |

| 80 | 90 | 5 | 6 |

| 80 | 95 | 7.5 | 6 |

| 80 | 100 | 10 | 6 |

| 85 | 100 | 7.5 | 6 |

| 90 | 105 | 7.5 | 6 |

| 100 | 115 | 7.5 | 6 |

| 100 | 120 | 10 | 6 |

| 100 | 125 | 12.5 | 6 |

| 110 | 125 | 7.5 | 6 |

| 110 | 130 | 10 | 6 |

| 115 | 130 | 7.5 | 6 |

| 120 | 140 | 10 | 6 |

| 120 | 145 | 12.5 | 6 |

| 120 | 150 | 15 | 6 |

| 125 | 145 | 10 | 6 |

| 125 | 150 | 12.5 | 6 |

| 130 | 150 | 10 | 6 |

| 140 | 160 | 10 | 6 |

| 140 | 165 | 12.5 | 6 |

| 140 | 170 | 15 | 6 |

| 145 | 170 | 12.5 | 6 |

| 145 | 175 | 15 | 6 |

| 150 | 170 | 10 | 6 |

| 150 | 180 | 15 | 6 |

| 160 | 180 | 10 | 6 |

| 160 | 185 | 12.5 | 6 |

| 160 | 190 | 15 | 6 |

| 160 | 200 | 20 | 6 |

| 180 | 200 | 10 | 6 |

| 180 | 210 | 15 | 6 |

| 180 | 220 | 20 | 6 |

| 200 | 220 | 10 | 6 |

| 200 | 230 | 15 | 6 |

| 200 | 245 | 22.5 | 6 |

| 250 | 300 | 25 | 6 |

Other sizes of metric honed tubes are also available on customer’s request.

As the professional China honed tube manufacturer and hydraulic cylinder honed tube suppliers, our factory also manufactures and supplies hydraulic honed tube sizes in a wide range of inch dimensions.

Chart 2. Imperial honed cylinder tubing sizes

| Inside Diameter | Outside Diameter | Wall Thickness | Weight / Foot |

| (Inch) | (Inch) | (Inch) | (Lbs.) |

| 1 | 1.5 | 0.25 | 3.337 |

| 1.125 | 1.5 | 0.188 | 2.634 |

| 1.25 | 1.625 | 0.188 | 2.885 |

| 1.375 | 1.75 | 0.188 | 3.136 |

| 1.5 | 1.75 | 0.125 | 2.169 |

| 1.5 | 1.875 | 0.188 | 3.379 |

| 1.5 | 2 | 0.25 | 4.673 |

| 1.625 | 2 | 0.188 | 3.63 |

| 1.75 | 2 | 0.125 | 2.503 |

| 1.75 | 2.125 | 0.188 | 3.88 |

| 1.75 | 2.25 | 0.25 | 5.34 |

| 1.875 | 2.25 | 0.188 | 4.13 |

| 2 | 2.375 | 0.188 | 4.38 |

| 2 | 2.5 | 0.25 | 6.008 |

| 2 | 2.75 | 0.375 | 9.512 |

| 2 | 3 | 0.5 | 13.35 |

| 2.125 | 2.5 | 0.188 | 4.631 |

| 2.125 | 2.75 | 0.313 | 8.135 |

| 2.25 | 2.5 | 0.125 | 3.171 |

| 2.25 | 2.625 | 0.188 | 4.881 |

| 2.25 | 2.75 | 0.25 | 6.675 |

| 2.25 | 3 | 0.375 | 10.513 |

| 2.25 | 3.25 | 0.5 | 14.685 |

| 2.375 | 2.5 | 0.063 | 1.627 |

| 2.375 | 2.75 | 0.188 | 5.131 |

| 2.5 | 2.75 | 0.125 | 3.504 |

| 2.5 | 2.875 | 0.188 | 5.382 |

| 2.5 | 3 | 0.25 | 7.343 |

| 2.5 | 3.125 | 0.313 | 9.387 |

| 2.5 | 3.25 | 0.375 | 11.514 |

| 2.5 | 3.5 | 0.5 | 16.02 |

| 2.75 | 3.125 | 0.188 | 5.882 |

| 2.75 | 3.25 | 0.25 | 8.01 |

| 2.75 | 3.5 | 0.375 | 12.516 |

| 2.75 | 3.625 | 0.438 | 14.894 |

| 2.875 | 3.5 | 0.313 | 10.638 |

| 2.875 | 4 | 0.563 | 20.651 |

| 3 | 3.25 | 0.125 | 4.172 |

| 3 | 3.375 | 0.188 | 6.383 |

| 3 | 3.5 | 0.25 | 8.678 |

| 3 | 3.625 | 0.313 | 11.055 |

| 3 | 3.75 | 0.375 | 13.517 |

| 3 | 4 | 0.5 | 18.69 |

| 3 | 4.500* | 0.75 | 30.038 |

| 3.25 | 3.5 | 0.125 | 4.506 |

| 3.25 | 3.625 | 0.188 | 6.884 |

| 3.25 | 3.75 | 0.25 | 9.345 |

| 3.25 | 3.875 | 0.313 | 11.89 |

| 3.25 | 4 | 0.375 | 14.518 |

| 3.25 | 4.25 | 0.5 | 20.025 |

| 3.5 | 3.75 | 0.125 | 4.839 |

| 3.5 | 3.875 | 0.188 | 7.384 |

| 3.5 | 4 | 0.25 | 10.013 |

| 3.5 | 4.125 | 0.313 | 12.724 |

| 3.5 | 4.25 | 0.375 | 15.519 |

| 3.5 | 4.5 | 0.5 | 21.36 |

| 3.5 | 4.75 | 0.625 | 27.534 |

| 3.625 | 4 | 0.188 | 7.653 |

| 3.75 | 4 | 0.125 | 5.173 |

| 3.75 | 4.25 | 0.25 | 10.68 |

| 3.75 | 4.5 | 0.375 | 16.521 |

| 4 | 4.375 | 0.188 | 8.385 |

| 4 | 4.5 | 0.25 | 11.348 |

| 4 | 4.625 | 0.313 | 14.393 |

| 4 | 4.75 | 0.375 | 17.522 |

| 4 | 5 | 0.5 | 24.03 |

| 4 | 5.25 | 0.625 | 30.872 |

| 4 | 5.750* | 0.875 | 45.557 |

| 4.25 | 4.75 | 0.25 | 12.015 |

| 4.25 | 5 | 0.375 | 18.523 |

| 4.5 | 5 | 0.25 | 12.683 |

| 4.5 | 5.125 | 0.313 | 16.062 |

| 4.5 | 5.25 | 0.375 | 19.524 |

| 4.5 | 5.5 | 0.5 | 26.7 |

| 4.75 | 5.25 | 0.25 | 13.35 |

| 4.75 | 5.5 | 0.375 | 20.526 |

| 5 | 5.25 | 0.125 | 6.842 |

| 5 | 5.5 | 0.25 | 14.018 |

| 5 | 5.625 | 0.313 | 17.73 |

| 5 | 5.75 | 0.375 | 21.527 |

| 5 | 6 | 0.5 | 29.37 |

| 5 | 6.25 | 0.625 | 37.547 |

| 5.25 | 5.75 | 0.25 | 14.685 |

| 5.25 | 6 | 0.375 | 22.528 |

| 5.25 | 6.25 | 0.5 | 30.705 |

| 5.5 | 6 | 0.25 | 15.353 |

| 5.5 | 6.25 | 0.375 | 23.529 |

| 5.5 | 6.5 | 0.5 | 32.04 |

| 5.5 | 7.000* | 0.75 | 50.063 |

| 5.75 | 6.5 | 0.375 | 24.531 |

| 5.75 | 6.75 | 0.5 | 33.375 |

| 6 | 6.25 | 0.125 | 8.177 |

| 6 | 6.375 | 0.188 | 12.39 |

| 6 | 6.5 | 0.25 | 16.688 |

| 6 | 6.625 | 0.313 | 21.068 |

| 6 | 6.75 | 0.375 | 25.532 |

| 6 | 7 | 0.5 | 34.71 |

| 6 | 7.25 | 0.625 | 44.222 |

| 6 | 7.500* | 0.75 | 54.068 |

| 6 | 8.000* | 1 | 74.76 |

| 6.25 | 6.75 | 0.25 | 17.355 |

| 6.25 | 7 | 0.375 | 26.533 |

| 6.25 | 7.25 | 0.5 | 36.045 |

| 6.5 | 7 | 0.25 | 18.023 |

| 6.5 | 7.25 | 0.375 | 27.534 |

| 6.5 | 7.5 | 0.5 | 37.38 |

| 6.5 | 7.75 | 0.625 | 47.559 |

| 6.5 | 8.000* | 0.75 | 58.073 |

| 6.75 | 7.5 | 0.375 | 28.536 |

| 7 | 7.5 | 0.25 | 19.358 |

| 7 | 7.75 | 0.375 | 29.537 |

| 7 | 8 | 0.5 | 40.05 |

| 7 | 8.25 | 0.625 | 50.897 |

| 7 | 8.500* | 0.75 | 62.078 |

| 7 | 9.000* | 1 | 85.44 |

| 7.25 | 8 | 0.375 | 30.538 |

| 7.25 | 8.25 | 0.5 | 41.385 |

| 7.25 | 8.750* | 0.75 | 64.08 |

| 7.5 | 8 | 0.25 | 20.693 |

| 7.5 | 8.25 | 0.375 | 31.539 |

| 7.5 | 8.5 | 0.5 | 42.72 |

| 7.5 | 9.000* | 0.75 | 66.083 |

| 7.75 | 8.5 | 0.375 | 32.541 |

| 8 | 8.5 | 0.25 | 22.028 |

| 8 | 8.75 | 0.375 | 33.542 |

| 8 | 9 | 0.5 | 45.39 |

| 8 | 9.25 | 0.625 | 57.572 |

| 8 | 9.500* | 0.75 | 70.088 |

| 8 | 10.000* | 1 | 96.12 |

| 8.25 | 9 | 0.375 | 34.543 |

| 8.25 | 9.25 | 0.5 | 46.725 |

| 8.5 | 9 | 0.25 | 23.363 |

| 8.5 | 9.5 | 0.5 | 48.06 |

| 8.5 | 10.000* | 0.75 | 74.093 |

| 8.75 | 9.75 | 0.5 | 49.395 |

| 9 | 10 | 0.5 | 50.73 |

| 9 | 10.25 | 0.625 | 64.247 |

| 9 | 10.500* | 0.75 | 78.098 |

| 9.25 | 10 | 0.375 | 38.548 |

| 9.25 | 10.25 | 0.5 | 52.065 |

| 9.25 | 10.5 | 0.625 | 65.916 |

| 9.75 | 10.5 | 0.375 | 40.551 |

| 10 | 10.75 | 0.375 | 41.552 |

| 10 | 11 | 0.5 | 56.07 |

| 10 | 11.500* | 0.75 | 86.108 |

| 10 | 11.750* | 0.875 | 101.627 |

| 10 | 12.000* | 1 | 117.48 |

| 10.5 | 12.000* | 0.75 | 90.113 |

| 11 | 12 | 0.5 | 61.41 |

| 12 | 14.000* | 1 | 138.84 |

| 14 | 16.000* | 1 | 160.2 |

Our imperial size (inch size) honed tube can be customized according to the specific requirements of our customers, ensuring that we can meet the diverse needs of various industries.

Furthermore, our skilled engineers and technicians are readily available to offer technical assistance and advice to our clients, guaranteeing the production of top-notch honed tubes that meet the precise requirements of their applications. Whether you require metric or imperial sized honed tubes, our facility is equipped with the necessary capabilities and knowledge to manufacture them to the utmost standards of excellence and efficiency.

Advantages of Our Honed tube

Our honed tubes offer a multitude of advantages that set them apart from other options on the market.

- Firstly, our honed tubes boast high precision tolerances, meeting ID tolerance H7, H8, H9, and more, tailored to the specific requirements of our customers. This level of precision ensures a perfect fit and performance in hydraulic cylinder applications.

- Furthermore, our honed tubes are crafted from seamless cold drawn tubes, providing exceptional high pressure resistance. This feature guarantees the reliability and durability of our honed tubes, making them the ideal choice for applications where pressure is a key consideration.

- In addition to their high pressure resistance, our honed tubes also feature a smooth inside surface with a maximum roughness of Ra 0.4 microns ID finish (16Max Ra ID Finish). This smooth surface reduces friction and wear, prolonging the life of the hydraulic cylinder and enhancing its performance.

- Moreover, we offer flexible order quantities, accommodating even single unit requests for hydraulic cylinder tubing production and supply. This flexibility allows our customers to order the precise amount they need, reducing waste and ensuring cost-effectiveness.

- Lastly, our honed steel tubing boasts excellent weldability, making it a versatile and highly useful material in the production of cylinders. This feature allows for easy assembly and customization, further enhancing the functionality and performance of the hydraulic system.

In conclusion, our honed tubes offer a combination of precision, durability, performance, and flexibility that make them the top choice for hydraulic cylinder applications.

Honed Tubing Tolerance Standard

Our honed ID tubing can be supplied with ID tolerance of H7, H8, H9, H10 and H11 depends on customers’ request. The following table provides a breakdown of the various Inside Diameter tolerance values that are available.

Inner Diameter | Inner Diameter Tolerance | Honed Tube Wall Thickness Tolerance | ||||

H7 | H8 | H9 | H10 | H11 | ||

30 | + 0.021 0 | + 0.033 0 | + 0.052 0 | + 0.084 0 | + 0.130 0 | ±5% |

> 30-50 | + 0.025 0 | + 0.039 0 | + 0.062 0 | + 0.100 0 | + 0.160 0 | |

> 50-80 | + 0.030 0 | + 0.046 0 | + 0.074 0 | + 0.120 0 | + 0.190 0 | |

> 80-120 | + 0.035 0 | + 0.054 0 | + 0.087 0 | + 0.140 0 | + 0.220 0 | |

> 120-180 | + 0.040 0 | + 0.063 0 | + 0.100 0 | + 0.160 0 | + 0.250 0 | |

> 180-250 | + 0.046 0 | + 0.072 0 | + 0.115 0 | + 0.185 0 | + 0.290 0 | |

> 250-315 | + 0.052 0 | + 0.081 0 | + 0.130 0 | + 0.210 0 | + 0.320 0 | |

> 315-400 | + 0.057 0 | + 0.089 0 | + 0.140 0 | + 0.230 0 | + 0.360 0 | |

For imperial size honed tube, we usually make the ID tolerance 0/+0.003″ (for size below 7″) or 0/+0.005″ (for size over 7″) depends on the dimension of the honed ID dimension.

Outside Diameter Tolerance: As per the corresponding production standards such as DIN 2391, EN10305-1, ASTM A519, and so on; or upon customers’ request.

Honed tubes/ Hydraulic cylinder tube: Available Materials

Hydraulic cylinder tube is known as honed tube also, as it is usually used to produce hydraulic cylinder body, so it is called hydraulic cylinder barrel commonly too.

Our factory manufactures many different steel grades for hydraulic cylinder tubes, to meet your specific needs. Here below are the most popular materials.

- Carbon steel ST52, ST52.3,

- Carbon steel E355

- Steel SAE 4140: also known as 42CrMo

- Steel 27SiMn

- Carbon steel SAE 1020, Chinese 20#, C20

- Stainless steel 304

- Stainless steel 316

Yiwu Hydraulics is a professional manufacturer & supplier of honed tubes for cylinders, our factory manufactures all these materials of honed cylinder tubes.

[ Content ]

- Honed cylinder tubes of material ST52 /ST52.3

- Honed tubes of material E355

- Honed cylinder tubes of material SAE 1020

- SAE 4140 hydraulic cylinder barrel tubes

- 27SiMn honed tubes

- 20MnV6 hydraulic cylinder tubes

- Stainless steel honed tubes

Hydraulic cylinder tube of material ST52 /ST52.3

The ST52 /St 52.3 honed cylinder tubes produced by our factory are made of steel grade ST52 /St52.3 and conform to the DIN 2391 standard (DIN 2391 /BKS). These tubes are referred to as cold drawn seamless honed tubes and are subjected to a stress relieved heat treatment as per BKS standards. The following is a specification of the steel ST52:

| Grade | Chemistry | % | Yield | Tensile | Elongation | Typical Hardness |

|---|---|---|---|---|---|---|

| min. Mpa | min. Mpa | % in 2″ section | Min | |||

| ST52.3 | Carbon | 0.140 – 0.180 | 420 | 580 | 15 | B-80 |

| Si | 0.150 – 0.300 | |||||

| Mn | 1.200 – 1.400 | |||||

| P | 0.020 max | |||||

| S | 0.010 max |

Honed tubes of material E355

E355 honed pipes are cylinder tubes honed from steel tube grade E355 and in compliance with EN 10305-1 standard. This material is the equivalent of ST52 / St52.3. These honed cylinder tubes are usually referred to as cold drawn seamless honed tubes, as per the EN10305-1 /E355 +SR specification. The “+SR” indicates that these tubes have undergone a stress relieved heat treatment process.

Here below is the specification of the steel E355.

| Grade | Chemistry | % | Yield | Tensile | Elongation | Typical Hardness |

|---|---|---|---|---|---|---|

| min. Mpa | min. Mpa | % in 2″ section | Min | |||

| E355 | Carbon | 0.140 – 0.180 | 420 | 580 | 15 | B-80 |

| Si | 0.150 – 0.300 | |||||

| Mn | 1.200 – 1.400 | |||||

| P | 0.020 max | |||||

| S | 0.010 max |

Material ST52 /ST52.3 and E355 is also widely used to produce chrome plated hollow bar, which is also known as chrome plated OD tubes.

Hydraulic cylinder tube of material SAE 1020

SAE 1020 hydraulic cylinder tubes are honed steel tubes manufactured from low carbon steel grade SAE 1020, which is equivalent to Chinese steel grade 20#. This steel is known for its low hardness and low tensile strength. Compared to ST52 honed pipes, SAE 1020 honed tubes are cost-effective and can be utilized in a variety of applications. These honed tubes are finished with high precision to ensure dimensional accuracy and smooth surface.

| Grade | Chemistry | % | Yield | Tensile | Elongation | Typical Hardness |

|---|---|---|---|---|---|---|

| Min. Mpa | Min. Mpa | % in 2″ section | Min | |||

| 1020 | Carbon | 0.150 – 0.200 | 375 | 485 | 15 | B-75 |

| Mn | 0.300 – 0.600 | |||||

| P | 0.035 Max | |||||

| S | 0.035 Max |

SAE 4140 hydraulic cylinder barrel tube

SAE 4140 honed cylinder tubes are cold drawn seamless honed tubes made of steel grade SAE4140. 4140 hydraulic cylinder barrel tubes usually are used for applications under high pressure & heavy duty. As the tensile strength and yield strength of SAE 4140 is very high. Steel 4140 is equal to German steel grade of 42CrMo.

Below is the chemical composition of 4140 material.

| SAE 4140 /42CrMo | C% | Si% | Mn% | P% | S% | Cr% | Mo% |

| Min | 0.36 | 0.1 | 0.65 | 0.75 | 0.15 | ||

| Max | 0.44 | 0.4 | 1.1 | 0.04 | 0.04 | 1.2 | 0.35 |

Here below are the mechanical properties of SAE 4140.

| 4140 / 42CrMo | Yield strength | Tensile Strength | Elongation | Hardness HB |

| Min | 800 Mpa /115K psi | 900 Mpa /130K psi | 20% | 270 HB |

Steel 4140 / 42CrMo is also an idea material for manufacturing chrome plated shafting. Benefit for its high yield strength and tensile strength, 4140 chrome plated bar is usually used for applications where high strength is required.

27SiMn honed tube

The 27SiMn steel is another option for honed tube production, though it’s not as widely used as ST52.3/E355. This material is suitable for special applications that require unique properties.

27SiMn steel material chemical composition: C: 0.24-0.32%, Si: 1.10-1.40%, Mn: 1.10-1.40%.

27SiMn steel material mechanical properties: tensile strength min. 980 MPa; yield strength: min. 835 MPa; elongation after fracture: 12%; reduction of area: 40%; impact energy: 39J.

The honed tubes made from this material 27SiMn are known for their high strength and versatility in various applications.

20MnV6 hydraulic cylinder tube

20MnV6 honed tubes, made of carbon-manganese steel alloyed with vanadium, are a popular choice for hydraulic cylinder honed tubes due to their high tensile strength range of 600-790 MPa and high yield strength range of 440-650 MPa. The tubes are typically supplied in a black hot rolled condition, and are ideal for applications requiring super high strength. The combination of carbon, manganese, and vanadium makes 20MnV6 honed tubes a robust and durable choice for demanding applications.

Here below is the detailed specification of steel 20MnV6

| 20MnV6 Chemical Composition (Base Material) | ||

| Min % | Max % | |

| Carbon | 0.16 | 0.22 |

| Silicon | 0.10 | 0.35 |

| Manganese | 1.13 | 1.60 |

| Vanadium | 0.08 | 0.15 |

| Phosphorous | 0.00 | 0.03 |

| Sulphur | 0.02 | 0.04 |

| 20MnV6 Mechanical Property | ||

| Typical Mechanical Properties – As Supplied in the Black Hot Rolled Condition | ||

| Tensile Strength Mpa | 690 | |

| Yield Strength Mpa | 500 | |

| Elongation % | 21 | |

| Hardness HB | 210 | |

| Typical (Minimum) Mechanical Properties – Water Quenched at 925 °C and Tempered at 580 °C | ||

| Tensile Strength Mpa Min. Wall Thickness (mm) | <20mm | 750 |

| 20mm to 25mm | 700 | |

| <=30mm | 650 | |

| Yield Strength Mpa Min. Wall Thickness (mm) | <20mm | 650 |

| 20mm to 25mm | 620 | |

| <=30mm | 570 | |

| Elongation % Wall Thickness | <20mm | 16 |

| >20mm | 17 | |

| Impact J | +20°C | 40 |

| 0°C | 32 | |

| -20°C | 28 |

Stainless steel honed tubes

Stainless steel honed hydraulic cylinder tubes are an ideal choice for applications that demand high resistance to corrosion. These honed tubes, made of stainless steel, provide the necessary protection against harsh environments and corrosive substances. They are often used in industries such as food processing, chemical processing, and marine, where resistance to corrosion is a top priority. With their robust construction and corrosion-resistant properties, stainless steel honed hydraulic cylinder tubes are the ideal solution for applications that require high performance and durability.

Stainless Steel grades for honed tubes

| Grade | Chemical composition | % | Yield | Tensile | Elongation | Typical Hardness |

| PSI | PSI | % in 2″ section | Min | |||

| 304 | Carbon | 0.08 Max | 30,450 | 74,675 | 35 | B-90 |

| MN | 2 Max | |||||

| P | 0.035 Max | |||||

| S | 0.035 Max | |||||

| Ni | 8.0-11.0 | |||||

| Cr | 18.0-20.0 | |||||

| Si | 1.00 Max | |||||

| 316L | Carbon | 0.08 Max | 30,450 | 74,675 | 35 | B-90 |

| MN | 2 Max | |||||

| P | 0.035 Max | |||||

| S | 0.035 Max | |||||

| Ni | 10.0-15.0 | |||||

| Cr | 16.0-18.0 | |||||

| Si | 1.00 Max | |||||

| Mo | 2.0-3.0 |

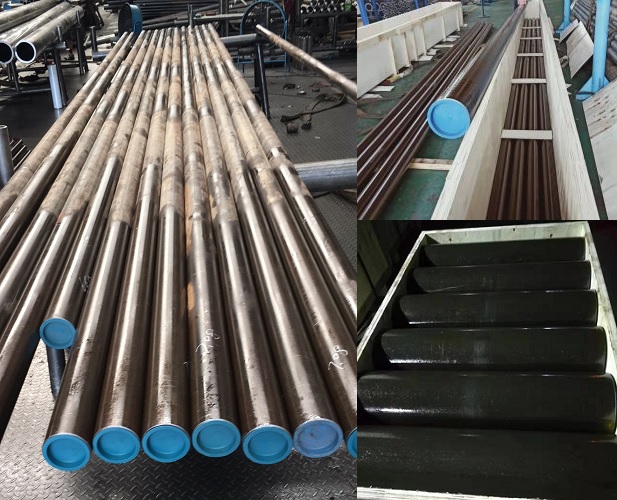

Packing method of Honed tubes

Protecting and securing a honed tube during transportation and storage is crucial to ensure it arrives undamaged and in good condition. There are various packing methods available for hydraulic honed cylinder tubes, each designed to provide adequate protection from impact, abrasion, moisture, and dust.

One common packing method involves placing the honed tube inside a wooden crate that is specially designed to fit its size and shape. The crate is then secured with screws or nails to prevent any movement during transit. Another option is to wrap the honed tube in steel banding, which is tightened using a ratchet tool to provide additional protection.

For added protection from moisture and dust, the honed tube can also be covered in plastic wrap before being secured with steel banding or tape. Alternatively, the tube can be placed inside a large plastic bag, which is then sealed and secured.

It is important to note that before packing, each honed tube should be oiled to prevent rusting. The specific packing method chosen will depend on factors such as the size and weight of the tube, the shipping distance, and any specific requirements from the customer. By selecting the appropriate packing method, the honed tube can be safely transported and stored until it is ready for use.

Our factory specializes in producing top-quality honed tubes and hydraulic cylinder honed tubes using our unique “Suitable To Hone” Cold Drawn Seamless Steel Tubes (CDS tubes). Through a meticulous honing process that utilizes abrasive polishing stones and paper, we are able to achieve precise ID dimensions and a smooth inner surface. In addition, we also utilize the SRB (skiving and roller burnishing) process to ensure extra precision in our honed tubing.

Our specially designed Honed tube for hydraulic cylinder is ready to be used directly in hydraulic cylinder applications, eliminating the need for further internal diameter (ID) processing. This not only saves time but also reduces costs for the production or repair of hydraulic cylinders.

Company Introduction: one of leading hydraulic cylinder honed tube suppliers in China

Our company Yiwu Hydraulics is one of the leading China hydraulic honed tube suppliers and manufacturers located in Wuxi, Jiangsu. For the past three decades, we have been producing and supplying honed pipes with a diverse range of dimensions and materials including SAE1020, ST52, SAE1045, 4140, and stainless steel. Our facilities encompass 65000 square meters, including a specialized factory for honed tubes and another for hard chrome plated shafts and chrome plated od tubing. Our team of 200 employees, including 25 dedicated to quality and technology, is committed to providing our customers with the best possible products and services.

Our advantages

Here are some of the advantages that customers appreciate about our products and services include:

- Rich and mature manufacturing experience: Our factory has nearly 30 years of experience in producing honed cylinder tubes, which gives us a strong understanding of customer needs and allows us to provide high-quality products (honed id tubing etc).

- Advanced manufacturing equipment and facilities: Our state-of-the-art manufacturing equipment and facilities allow us to produce honed tubes with high precision and consistency. We also regularly maintain and upgrade our machinery to ensure their performance.

- High-quality raw materials: We source our raw materials from reputable steel manufacturers in China such as TPCO, SHA STEEL, BAO STEEL, ensuring that our honed tubes are made with premium-quality materials.

- High precision: Our honed tubes are manufactured with tight tolerance and high-dimension precision, which is important for hydraulic cylinder applications. Tolerance can be ISO H7, H8 or H9, H10, depends on the sizes and customers’ request.

- Reliable Packing: All the honed pipe will be oiled by the anti-rust oil before delivery. And to protect the inner diameter surface of the honed ID tubing, we will cap the tube ends with plastic end caps, or if customer request we can weld a steel cap to protect the inner diameter of the honed id tubing during loading and unloading. And then the honed pipes will be packed with seaworthy package such as wooden cases or plastic bags.

- Strictly quality control: Our factory has a QC team of more than 10 persons. Our quality control team inspects each honed cylinder tube before shipment, using various tests to ensure their quality and consistency. The tests including Chemical Analysis Test, Tensile Test, Dimension Inspection, Roughness Test, Chrome plated thickness test, straightness inspection, and other tests according to standards and customer’s requirements.

- Mature quality management system: Our Total Quality Management system ensures that all aspects of our business related to product quality are well-controlled and monitored.

Our honed cylinder tubes have been exported to customers worldwide, serving a wide range of applications including hydraulic cylinders for different machinery. We have earned a strong reputation among our customers in China and in other countries such as the USA, Canada, Mexico, Colombia, Saudi Arabia, UAE, South Africa, Russia, Belarus, Thailand, Indonesia, Vietnam, Australia, Ukraine, Brazil, Turkey, Korea, New Zealand, Singapore, and Kuwait.

Popular Questions and Answers

Question 1: How do you guarantee the quality of the hydraulic cylinder tube?

Answer: Our hydraulic cylinder tube factory is committed to ensuring top-notch quality by adhering to a comprehensive Total Quality Management System. We procure our mother tubes from reputable Chinese steel manufacturers like TPCO, Sha-Steel, and Huaigang Special Steel. Each honed tube for hydraulic cylinder undergoes rigorous inspection before being packaged, and they are accompanied by a mill test certificate that complies with EN 10204/3.1 standards.

Question 2: What measures are taken to safeguard the interior surface of honed tubes while in transit?

Answer: The inner diameter surface of honed ID tubing is shielded by using tube caps to seal both ends of each tube. These tube caps are commonly crafted from plastic and are available in either green or yellow hues. In the case of larger honed tubes with expanded inner diameters, steel caps can be affixed to the tube ends through welding, as per customer preference.

Question 3: What is the delivery time of hydraulic cylinder honed tubes?

Answer: As one of the largest hydraulic honed tube suppliers in the area, we stock a lot of different sizes and materials of mother tubes for honed tubes, so normally our delivery time is around 20 days depends on the quantity and size. And our company has a flexible production system that can meet the urgent needs of customers. Additionally, we have a professional logistics team that can ensure safe and fast delivery of products to customers all over the world.

Question 4: Have you exported your honed pipes to overseas countries? If so, what is your main overseas market?

Answer: Yes, we have exported our hydraulic cylinder honed tubes to various countries, including the USA, Russia, Australia, the UAE, Vietnam, Saudi Arabia, South Africa, Canada, Brazil, Mexico, Thailand, and France. These countries make up our main overseas markets as a leading supplier in China.

Question 5: Is your company hydraulic cylinder tube manufacturers or trading company?

Answer: Yes, we are true hydraulic cylinder tube factory company located in Wuxi, Jiangsu, we are one of the professional hydraulic cylinder tube manufacturers in China, we welcome customers to come to visit our factory. Then you can see the details.

How to buy Hydraulic Cylinder Tube from us?

Are you looking to buy Hydraulic Cylinder Tube from our company?

We specialize in providing top-quality hydraulic honed cylinder tubes and offer comprehensive technical assistance. As a reputable manufacturer and supplier based in China, we are dedicated to delivering superior honed tubes to meet our customers’ needs. If you are interested in acquiring honed tubes or want to learn more about our offerings, please feel free to contact us through the following channels:

Email: [email protected]

TEL: +86177-7580-7583

Please simple tell us the OD, ID, Length, steel grades and quantities, we will make you an offer with our best prices and delivery time.