Honing process and Skiving & Roller burnishing (SRB) process are the two typical types of manufacturing processes for hydraulic cylinder tube.

Tube ID Honing Process

The honing process is utilized in our factory to achieve smooth surface finishes on the inside diameter of honed tubes, all while ensuring precise tolerances are maintained. This method involves the use of abrasive stones and paper to eliminate surface imperfections caused by the cold drawing process, ultimately reaching the desired dimensional tolerances and surface finish. Cutting fluids are commonly used to aid in the cutting process and to remove any excess material from the bore. During the production of honed tubes, our factory relies on the honing process to achieve smooth surface finishes and precise tolerances on the inside diameters.

Here below is a video which shows the cylinder tube honing operation.

Honing is a low velocity abrading process that differs from grinding. It generates less pressure and heat, so the surface, precision, and size of the finished product are not affected by heat stress. Precision cylinder tubes have excellent surface integrity and finish, high accuracy in inner diameter tolerances, and overall dimensions and geometry control that cannot be achieved with faster cutting speeds.

Tube ID Skiving and Roller Burnishing (SRB)

Skiving and roller burnishing processes were developed in the 1970s as an alternative to honing tubing for hydraulic cylinders. It is an extremely fast process when compared to honing, in the neighborhood of 70% to 80% faster.

It is capable of holding bore diameter tolerances to 0.025 mm (0.001 in.) The necessary equipment requires a large up-front investment, which makes it suitable for high-volume tubing production.

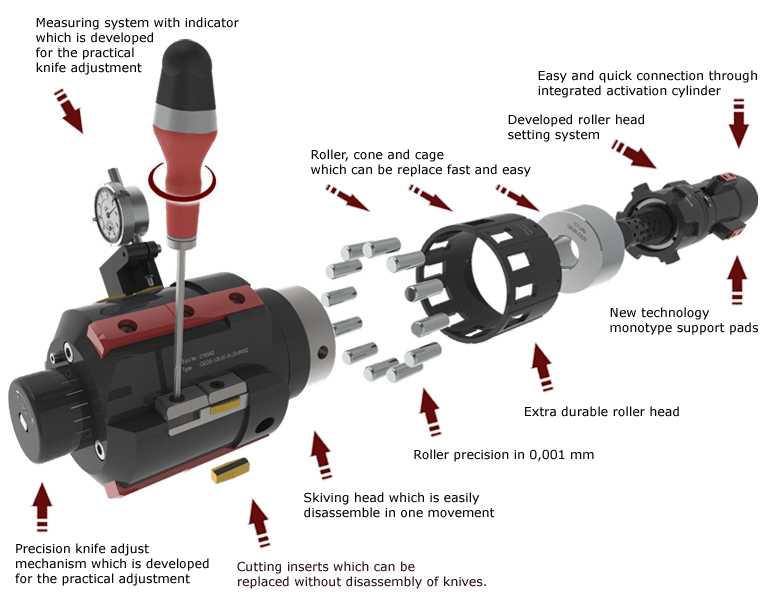

The skiving and roller-burnishing operation, as the name implies, actually involves two processes in one tool. The tube is end clamped in the machine and the tool advances inside. Coolant is pumped through the ID of the tube, flows around the tool and pushes chips out of the front of the tube during operation.

The first part of the tool contains carbide cutters that rotate and advance axially to remove material. This section performs the skiving. The second part of the tool contains hardened rollers that deform the peaks creating by skiving and produce an extremely smooth surface finish, thus roller burnishing.

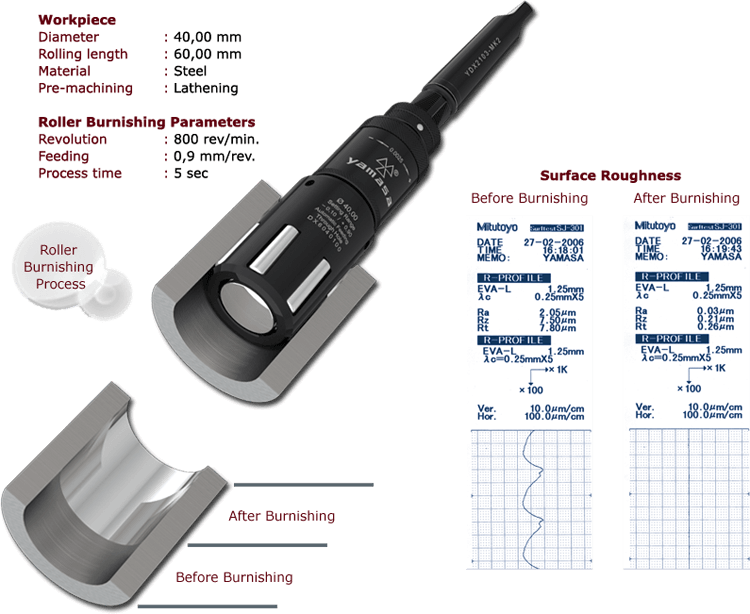

The process offers very fine surface finish, such as Ra = 0.05 to 0.20 µm. While roller burnishing generates a mirror-like result, however, there is not precise control of the surface finish.

In addition, burnishing creates a residual stress layer in the cylinder wall that improves fatigue life. Surface hardness increases approximately 50% in steel tubing.

Here below video is an introduction of hydraulic cylinder tube skiving and burnishing.

Skiving and roller burnishing process is faster than honing process; and typically generates more precise tolerances and better inside surface finish control than honing.

Here below is the features of honed tubes by Skiving and roller burnishing process.

Inside Diameter Range: 60-500 mm

Length of SRB tube: Up to 14 meters

Surface Roughness: Max Ra 0.4 microns.

Inside Diameter Tolerance: ISO – H7, H8, H9 on request.

Here below picture describes the main advantages of the skiving and burnishing process for manufacturing cylinder tubes.

Conclusions

Skiving and roller burnishing are the go-to processes for high-volume hydraulic cylinder production. However, honing remains a viable option for projects with lower output requirements. Many cylinder manufacturers utilize a combination of skiving and honing to meet varying production needs. Honing is particularly effective for low volume projects or for repairing and refurbishing cylinders of non-standard sizes.